3D Printing Technology in Living Tissue Production: Innovations and Advancements

3D printing technology has completely transformed the way we approach creating objects. It has now expanded its capabilities, to the field of biofabrication. This innovative technology allows us to build structures, including living tissues. Of using plastic or metal which are commonly used in 3D printing biofabrication involves working with bioinks composed of living cells. These cells are carefully layered to form tissue structures opening up possibilities for creating constructs that could potentially replicate the architecture of organs.

This process combines knowledge from fields such as biology, material sciences and mechanical engineering to turn the idea of producing tissues and organs into reality. By manipulating and placing cells within a scaffold we can stimulate their growth and natural interactions. This breakthrough technique holds potential for research and applications as it provides a platform for studying diseases, testing pharmaceuticals and even generating replacement tissues and organs that can be used in transplants.

Your involvement, in 3D bioprinting pushes the boundaries of medicine. It paves the way, for treatment options. Speeds up the progress of regenerative medicine. As the technology advances your ability to create living tissues grows, bringing us closer to the possibility of printing fully functional organs for medical use. This goes beyond replicating the shape of structures; it also involves ensuring that the printed tissues can function like their natural counterparts. It’s a balance between biology and mechanics one that requires precision, innovation and a deep understanding of biology.

Overview of 3D Bioprinting

To truly grasp the capabilities of 3D bioprinting we must first delve into its history explore the technologies that have been developed over time and understand its role in advancing tissue engineering.

History and Development

Technology has been evolving rapidly in decades. 3d bioprinting is no exception. It started as an extension of 3D printing but with a focus on creating living tissues instead of non living plastic objects. By the early 2000s, techniques derived from printing methods, like inkjet printing began to be adapted for bio-applications. With progress a fusion of engineering principles, biomaterials science and cellular research gave rise to forms of bioprinting capable of constructing complex tissue frameworks.

Key Technologies and Methods

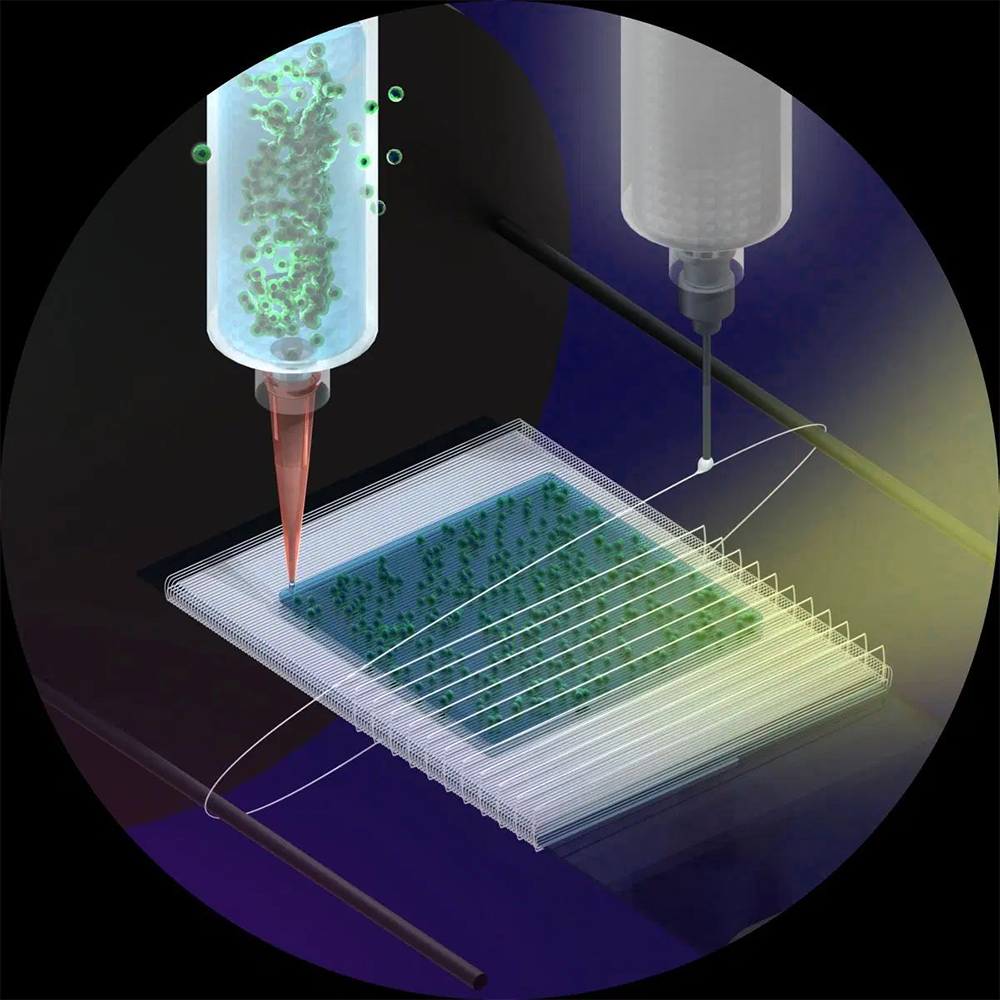

When exploring the field of 3D bioprinting you come across technologies:

- Inkjet Printing Technology: This technology lays down bioinks in drops, allowing for fine control over the placement of cells and biomaterials.

- Stereolithography: It employs a light source to selectively cure liquid resin — in the context of bioprinting, light-curable bioresins — into solid structures layer by layer.

- Laser-Assisted Bioprinting: Here, laser pulses are used to deposit layers of bioinks accurately, creating tissue scaffolds or even scaffold-free structures.

What these technologies have in common is their use of bioinks. A combination of living cells and biomaterials like hydrogels that mimic the matrix. Hydrogels provide support for cell growth. Are often employed in both scaffold-based and scaffold free approaches. An innovative technique called Freeform Reversible Embedding of Suspended Hydrogels (FRESH) allows for the printing of soft structures that were previously challenging to create.

Applications in Tissue Engineering

In the field of tissue engineering attention turns towards the applications of these technologies. 3D bioprinting has been utilized to fabricate tissues of replicating biological functions. Currently researchers are exploring the field of engineering tissues including skin, cartilage, bone and complex organs, like hearts and livers. The advancements in bioprinting techniques have allowed for the creation of scaffolds that support tissue structure and growth. Additionally there is a possibility of developing scaffold tissues that rely on the self assembly of cells. These developments in 3D bioprinting hold potential for treatments and regenerative medicine by enabling the reconstruction of damaged tissues caused by injury or disease.

Biomaterials and Bioinks

To fully grasp the concept of 3D bioprinting it is important to understand two components; biomaterials and bioinks. These elements serve as the foundation for creating structures that closely resemble human tissue complexity.

Properties of Biomaterials

To ensure the 3D printing of tissues it is important to have biomaterials, with properties. These biomaterials need to be compatible with the body to prevent rejection when implanted. Should have the necessary structural integrity to maintain tissue shape. Here are some key properties to consider:

- Biocompatibility: The biomaterials should not trigger a response in the body.

- Mechanical Stability: They should possess strength to handle both manipulation and natural physiological forces.

- Degradation Rate: The rate at which these biomaterials degrade should align with the healing process of body tissues as they will eventually be replaced.

Advancements in Bioink Formulations

Bioinks are a type of biomaterials that consist of living cells. They are customized to possess characteristics for printing tissue structures. Here’s what you need to understand about their formulation:

- Viscosity: It is crucial for maintaining the shape of a structure after printing. Bioinks need to be adjusted so that they can flow smoothly through the printer nozzle but solidify once they are deposited.

- Hydrogels: Popular bioinks often take the form of hydrogels due to their water content and similarity to the natural tissue environment. For example;

- Alginate hydrogel: It is a polymer that can encapsulate cells and is commonly used because of its viscosity.

- Collagen: It plays an integral role in providing tissues with structure and strength.

Natural vs. Synthetic Polymers: Bioinks can be derived from natural sources such as alginate and collagen or they can be synthesized to create new materials with customizable properties. The choice between synthetic polymers depends on the application and how they interact with the bodys biological processes.

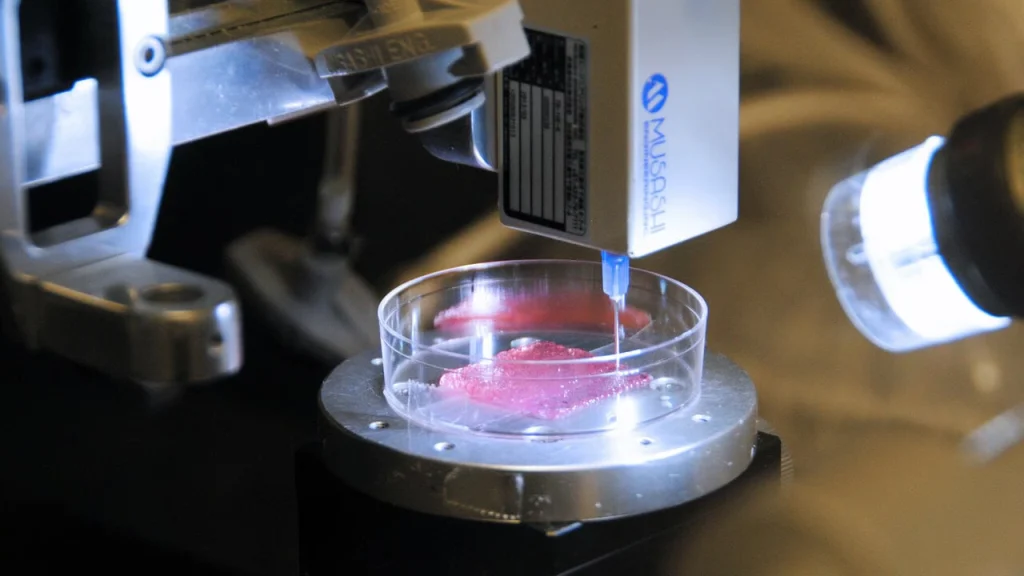

Bioprinting Living Tissues

Bioprinting involves using 3D printing technology to create living tissues. Cells are layered systematically to form structures while biomaterials are precisely deposited. The field of bioprinting is revolutionizing tissue engineering and organ printing by allowing placement of living cells layer by layer leading to the creation of tissues. The primary focus is, on replicating both the environment and structural complexity found in human tissues.

Cell Selection and Preparations

When starting the bioprinting process it is crucial to choose the cells that will be used as they greatly impact the success of the tissue. Typically living cells, like mesenchymal stem cells, endothelial cells and fibroblasts are selected due to their ability to differentiate and contribute to forming the matrix. To ensure their viability and functionality during printing these cells need to undergo a process called cell encapsulation. This involves:

- Isolating and expanding the cells until there is a quantity.

- Encapsulating the cells in a hydrogel that mimics their environment.

- Ensuring biocompatibility to prevent any immune rejection.

Tissue and Organ Printing

When delving into the realm of tissue and organ printing it’s important to grasp the complexity involved. This process requires a combination of biofabrication techniques to create structures such, as bone, cartilage and muscles. It’s crucial for these printed structures to incorporate a vascular network for systems that play a role in supplying nutrients and removing waste. During the printing procedure:

- Maturing tissues can be facilitated through the use of a bioreactor.

- Cartilage tissue engineering can greatly benefit from customizing shapes specifically tailored for damaged areas.

- The establishment of vascular networks within the tissue is essential for its long-term survival.

The ultimate objective is to develop tissues that’re well suited for biomedical applications, including organ replacement and repair. Integrating living cells into printed structures aims to achieve biocompatibility and functionality to tissues.

Challenges and Future Perspectives

As you delve deeper into the field of printing for living tissue production it’s crucial to acknowledge that it brings forth significant challenges requiring careful navigation and continuous innovative breakthroughs that shape the realm of possibilities.

Ethical Considerations and Regulatory Issues

It is imperative to acknowledge that advancements in bioprinting raise questions and pose regulatory hurdles. Personalized medicine holds promise in tailoring treatments, however concerns, about gene expression manipulation and human tissue manipulation also emerge. Regulatory bodies are currently working on developing guidelines to ensure the safety, ethics and effectiveness of tissues produced through 3D bioprinting, such, as valve conduits and bone grafts. It is important to consider hyaluronan hydrogels and scaffold free vascular tissue engineering in light of these standards well as subjecting them to rigorous testing before they can be used in regenerative medicine or drug screening.

Innovations in Tissue Maturation

Progress in biomimicry and microfluidics plays a role in the maturation of biofabricated tissues like cardiac pseudo tissues or printed bone tissue. These technologies help recreate the environments where cells thrive, enabling growth and differentiation factors to function effectively. When exploring treatments for conditions like arthritis that involve cartilage repair it is crucial to consider cell patterning technologies and the integration of stem cell lines. Additionally ongoing research into computer-aided jet-based 3D tissue engineering methods for creating human microvasculature fabrication shows promise, in addressing tissue damage and promoting tissue integration after implantation.